Making beer means converting starch into a fermented beverage.

Starch is a raw material of plant origin. A wide variety of plants produce starch which serves as an energy reserve. Since millenia, humans have used this extraordinary energy storage capacity of plants to brew their favourite fermented beverages, hence the numerous kinds of beer around the world.

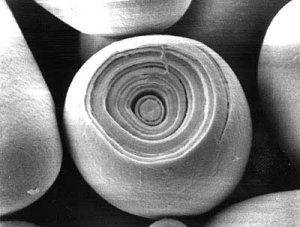

Starch is a polysaccharide, a macromolecule made up of long chains of simple sugars (glucoses, maltoses, etc.), more or less branched. These microscopic strands are folded, in their natural state, into granules. A chain of cereal starch connects about 104 simple sugars, and the albumen of a grain of barley, wheat, millet, rice or maize contains thousands of these starch granules. The tubers of cassava, yam, taro, sweet potato and potato contain millions of them. Achenes (dried fruits with protective shells: chestnuts, quinoa, buckwheat, amaranth, etc.) are rich in starch. Also the fruit of the carob tree. Some plants store starch in their roots or their vegetative system (e.g. the stipe of the sago palm). The plantain banana is a very rich starchy fruit (20% to 30% of starch).

Whenever plants require energy for their growth or reproduction (seeds, tubers), they store the chemical and photochemical energy accumulated during their plant cycle in the form of starch. The principle is invariant: the enzymatic degradation of the starch releases the sugars that the seed, tuber, root system or apical bud of a palm tree uses to feed the germ or bud when they develop.

Other families of macromolecules with a high energy potential are found in the plant kingdom: oils, mucilages, etc. Not forgetting the simple and natural sugars of fruits and sugar stems. With the latter, the plant world is exploring a strategy that is the opposite of the one pursued by starch: unsustainable storage of biochemical energy in a biochemically unstable (hydrated) environment of fermentable molecules (fructoses and glucoses are directly assimilated by yeasts, with or without oxygen).

15 to 10,000 years ago, the human species spotted this formidable energy potential of plant origin: the marvellous Starch, rich, storable and biochemically stable if kept dry. Exploited for food purposes, starch has become the basis of solid and liquid foods for the majority of human populations on the planet. This fundamental evolution was reinforced by the first farmers. In various parts of the world, human populations have switched to growing cereals or transplanting tubers. By gradually abandoning a way of life based entirely on gathering and hunting, these human groups relied mainly on starch to secure their subsistence throughout the year. Bread and beer were virtually born at this protohistorical moment, albeit its exact date must be ascertained for each world regions !

The social and technical consequences on a planetary scale of such a collective human gamble on a) starch (cereals and tubers), b) food plants (gardening and arboriculture), c) live and reproducible meat (breeding) - have not yet been exhausted to date.

Before the choice made by humans, it is therefore the biological strategies deployed by the plant kingdom to store, keep and use the biochemical energy that separate beer and wine [1]. The alcoholic fermentation of these 2 categories of beverage - even if they ultimately go through the same yeast metabolism - is based on 2 different raw materials of plant origin and chemical structure.

On the one hand, the plants produce fruit juices that are seasonal and perishable, but easily available and effortlessly assimilated by the human being because naturally drinkable. The simplicity of making the primitive wines seems obvious: spontaneous alcoholic fermentation of natural juices in the Garden of Eden. Neither work nor intelligence are need to enjoy the intoxication offered by a nature that has provided everything: water, sugars, acidity, yeasts and propicious temperatures.

On the other side, the Lord Starch, potentially rich in sugar, storable, but how difficult to transform in ist dried state. The yeast cell does not know how to assimilate such a large molecule: its size prevents it from passing through any cell wall. Moreover, most yeasts do not have any enzymatic complex that can cut starch into glucose molecules.

The breaking down of the starch chains must therefore be carried out before or during the yeast work, either biochemically or chemically. In order to provide the yeast with the sugars necessary for alcoholic fermentation, the raw starch must undergo several operations:

- Grinding of grains (cereals, grasses, other sources of starchy seeds) / Peeling and grating of tubers (manioc, yam, taro, potato, etc.) or starchy pith (sago palm) / Husking of dried fruit (carob seeds, chestnuts, etc.). This step is excluded if the grains are germinated (brewing path no 2).

- Prolonged soaking or cooking to break up the starch granules. Unfolded, the long starch chains can undergo hydrolysis. The flour + water mixture forms a starchy slush. This step is excluded if the grains are germinated (brewing path no. 2).

- Breakdown of starch chains into sugars by the action of specific enzymes (hydrolase class) or the action of an acidic chemical medium. This essential technical step is at the heart of the brewing process. It characterises the technical cycle of the beer and serves as the linchpin for its definition.

- A crushing of the malt grains if the grains have been made to germinate (Brewing path no. 2).

There are 6 methods for hydrolysing starch, whatever its origin and preparation. As far back as we can go in the history of beer and brewing, these 6 brewing methods have been applied and are all used today. The first 5 pathways are called "enzymatic": they use enzymes present in human or animal saliva (ptyalin), cereal seeds (amylases), fungi or moulds, tubers or other natural sources of starch. The 6th pathway is purely chemical.

Pathway no 1 = insalivate a starchy cooked dough

Pathway no 2 = make grains of cereal germinate

Pathway no 3 = grow amylolytic fungi on a starchy substrate

Pathway no 4 = use plants hosting one amylolytic biochemical complex

Pathway no 5 = Overripening of a starchy fruit

Pathway no 6 = acid hydrolysis of a starchy mash

[1] There is a 3rd category of fermented beverages: mead. The accumulation of energy in the form of sugar concentrate, honey, belongs mainly to the animal world, although the food chain of honey bees or wasps begins, as always, with a product from the plant world. The dairy alcoholic fermented beverages belong to a 4th group. Although these fermented beverages are very distinct from the beers, the lactic fermentation which is part of the process has played a technical role in the brewing of beer, contributing mainly to the acidic brewing pathway no 6, when and where pastoralists and farmers have maintained a close cooperation in the past.